Quick overview

140 - 1000 mm

Cross-section

drawing

| BL | V | S | Concealed view | h | kg |

|---|---|---|---|---|---|

| 140 | 79 | 60 | 0 | 25 | 3.4 |

| 170 | 124 | 100 | 0 | 25 | 4.0 |

| 220 | 174 | 150 | 0 | 25 | 5.0 |

| 250 | 204 | 180 | 0 | 25 | 5.7 |

| 300 | 264 | 240 | 0 | 25 | 6.7 |

| 310 | 264 | 240 | 0 | 25 | 7.0 |

| 350 | 304 | 280 | 0 | 25 | 7.8 |

| 370 | 324 | 300 | 0 | 25 | 8.2 |

| 400 | 354 | 330 | 0 | 25 | 8.9 |

| 500 | 454 | 430 | 1x46 | 25 | 11.4 |

| 600 | 564 | 540 | 1x46 | 25 | 13.4 |

| 620 | 574 | 550 | 1x46 | 25 | 13.9 |

| 700 | 654 | 630 | 1x46 | 25 | 15.7 |

| 740 | 694 | 670 | 1x46 | 25 | 16.5 |

| 800 | 754 | 730 | 1x46 | 25 | 17.8 |

| 930 | 884 | 860 | 2x46 | 25 | 20.9 |

| 1000 | 954 | 930 | 3x46 | 25 | 22.8 |

Product information

The level indicator type 411 serves as a liquid indicator in the bypass for reliable level control in boilers and tanks. The indicator has a square flange design with two rear 20 mm welding ends.

The level indicator is equipped with a sight glass plate made of high-quality borosilicate glass according to DIN 7081. This is securely encapsulated between gaskets and tightly screwed to ensure lasting tightness and high pressure resistance.

Standardly, the sight glass type 411 is made of stainless steel 1.4571 (316Ti) - a material characterized by high corrosion resistance and durability. Upon request, the design is also available in many other materials, suitable for specific requirements and applications.

The sealing of the level indicator is done with flat gaskets customized to your needs from an extensive material range. This offers more demanding materials in addition to the common fiber material gaskets, such as PTFE (Teflon®), novaphit® MST-XP, and KlingerSil® C4400.

Important note: Reflective sight glasses cannot be combined with mica discs and coatings, as the protective mica layer prevents the necessary light refraction for reflection.

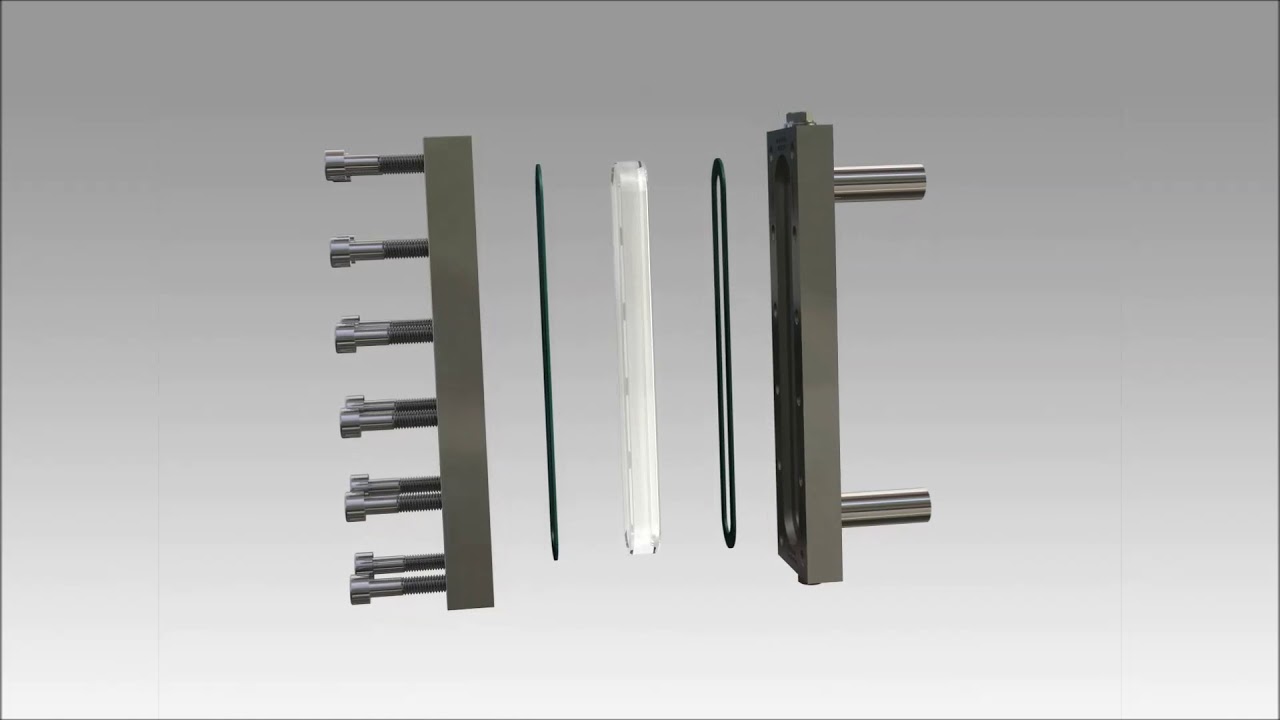

- Screws

- Cover frame

- Glass cushion

- Sight glass

- Gasket

- Base frame

- Welding ends

- Screw plugs