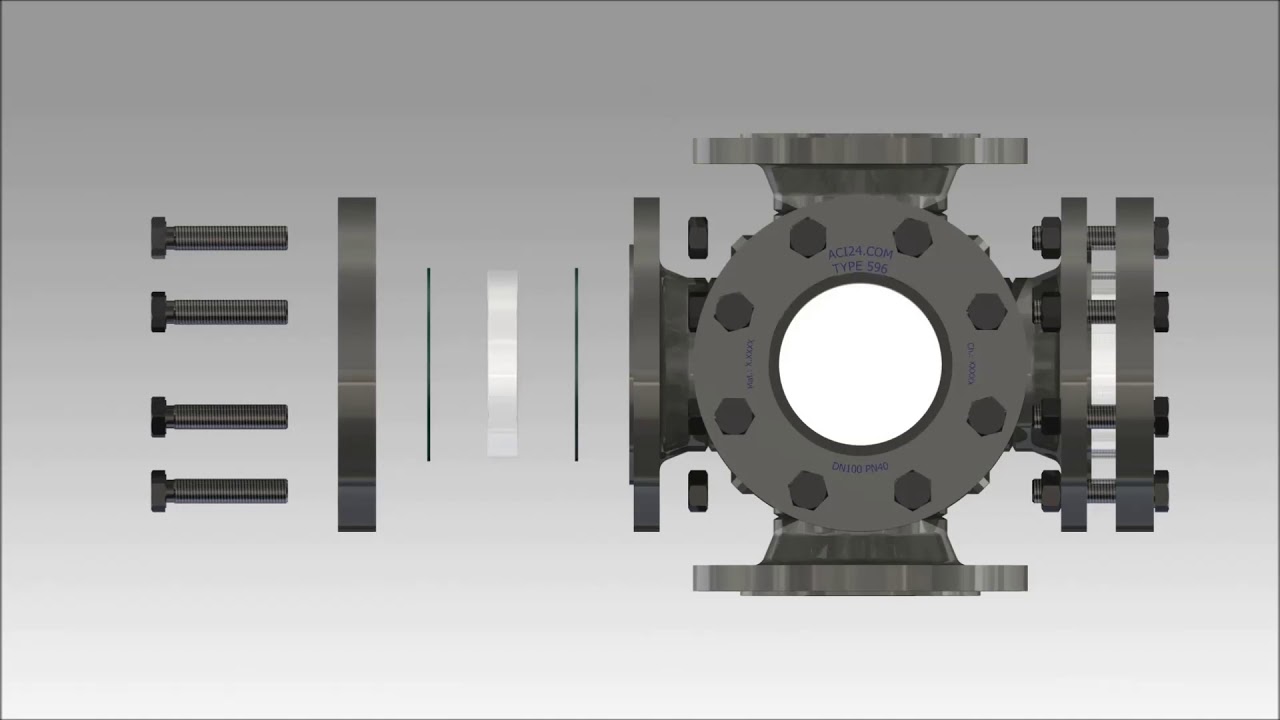

Flow sight glass type 596 PN 16/400

Sight glass with 4 viewports and flange connections according to DIN EN 1092-1

Flow sight glass PN 16 | PN 40 | PN 63 | PN 100 | PN 160 | PN 250 | PN 320 | PN 400

- 50

- 65

- 80

- 100

- 125

- 150

- 200

- 16

- 40

- 63

- 100

- 160

- 250

- 320

- 400

- 80°C

- 130°C

- 150°C

- 175°C

- 180°C

- 200°C

- 280°C

- 300°C

- 320°C

- Wiper SGW with PTFE or silicone wiper blade

- LED light for Ex and non-Ex areas

- FEP or Halar® coating

- Mica protection discs

- Double glazing type 596D

- Special constructions

Quick overview

DN 50 - 200

Cross-section

drawing

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|

| Total length (BL)² | DIN EN 558-1 FTF 2 | ||||||

| Flange dimensions | DIN EN 1092-1 | ||||||

| free view (D1)² | 55 | 70 | 83 | 107 | 132 | 159 | 207 |

2) All dimensions are executed – as far as constructionally possible – according to the standard. Otherwise, the information from the order confirmation and customer drawing applies.

Dimensions correspond to the nominal pressure level PN 16, other pressure levels may differ

Product information

The flow sight glass type 596 with 4 sight openings in 2-way design as a welded construction is a particularly robust version of our flow sight glasses.

A clear advantage of the version with four sight openings is that the user receives an almost 360° overview of the process – and that at very high operating pressures. This allows optimal observation of the flow of the medium and comprehensive control of the process.

Type 596 is designed for operating pressures up to 400 barg and can be easily installed between flanges according to DIN EN 1092-1. Thanks to its standard lengths according to DIN EN 558-1, the sight glass is ideally suited for retrofitting in existing systems.

Even with larger nominal sizes, high operating pressures can be achieved with type 596.

The standard version with borosilicate glass is suitable for operating temperatures up to 280 °C, with an additional mica protection disc even up to 300 °C or 320 °C in combination with MAXOS® safety sight glasses according to DIN 7080.

The sealing of the fitting is done with flat seals tailored to your needs from a comprehensive range of materials. This offers not only the common fiber material seals but also more demanding materials such as PTFE (Teflon®), NBR, novaphit® MST-XP, KlingerSil® C4400, and many other brand seals.