Longitudinal sight glass fitting type 330 PN 16/40

For welding in or on

Level indicator for working pressures up to 40 barg

- 140

- 170

- 220

- 250

- 300

- 310

- 350

- 370

- 400

- 500

- 600

- 620

- 700

- 740

- 800

- 930

- 1000

- 16

- 40

- 80°C

- 130°C

- 150°C

- 175°C

- 180°C

- 200°C

- 243°C

- 280°C

- 300°C

- 320°C

- 400°C

- FEP or Halar® coating

- Mica protection disc

- High temperature version

- Nearly dead space-free version

- Special constructions

Quick overview

140 - 1000 mm

Cross-section

drawing

| BL [mm] | 140 | 170 | 220 | 250 | 300 | 310 | 350 | 370 | 400 | 500 | 600 | 620 | 700 | 740 | 800 | 930 | 1000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SL [mm] | 79 | 124 | 174 | 204 | 264 | 264 | 304 | 324 | 354 | 454 | 564 | 564 | 654 | 694 | 754 | 884 | 954 |

| Concealed view [mm] | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1x46 | 1x36 | 1x46 | 1x46 | 1x46 | 1x46 | 2x46 | 3x46 |

| h1/h2 [mm] (PN 16) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Weight [kg] (PN 16) | 2,8 | 3,2 | 4,0 | 4,6 | 5,3 | 5,6 | 6,3 | 6,6 | 7,1 | 9,1 | 10,7 | 11,1 | 12,5 | 13,2 | 14,2 | 16,7 | 18,2 |

| h1/h2 [mm] (PN 40) | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Weight [kg] (PN 40) | 3,4 | 4,0 | 5,0 | 5,7 | 6,6 | 6,9 | 7,8 | 8,2 | 8,8 | 11,3 | 13,3 | 13,8 | 15,6 | 16,4 | 17,7 | 20,8 | 22,6 |

Product information

The ACI sight glass of type 330 is used for reliable observation of the liquid level in closed containers such as boilers, tanks, or silos. It is a rectangular vertical sight glass that can be either welded into the container wall or attached by welding.

The fitting is equipped with a sight glass plate made of high-quality borosilicate glass according to DIN 7081 (or comparable). This is securely framed between gaskets and tightly screwed to ensure permanent sealing and high pressure resistance.

Standardly, the sight glass type 330 is made of stainless steel 1.4571 (316Ti) – a material characterized by high corrosion resistance and durability. Upon request, the design is also available in many other materials, suitable for specific requirements and applications.

The sealing of the fitting is done with flat gaskets tailored to your needs from an extensive range of materials. In addition to the common fiber material gaskets, more sophisticated materials such as PTFE (Teflon®), NBR, novaphit® MST-XP, KlingerSil® C4400, and many other branded gaskets are also available.

If the maximum operating temperature of borosilicate glass according to DIN 7081 does not meet your requirements, or if the process conditions pose a problem even for the highly resistant borosilicate glass, a mica protection disc specially adapted for the fitting provides additional protection against temperature and steam. FEP or Halar® coatings also additionally protect the borosilicate glass from aggressive chemicals or alkaline solutions.

For applications in poorly lit containers, the use of a reflex sight glass according to DIN 7081 (or comparable) is recommended. These glasses are embedded with special prism structures that break and reflect the incoming light – thus, the filling level can be recognized much better.

If, however, the container is well-lit, the medium is very clear, or if the color of the medium should remain visible, a transparent sight glass is the better choice. It allows for an unaltered view and precise optical control of the contents.

Important note: Reflex sight glasses cannot be combined with mica discs and coatings, as the protective mica layer prevents the light refraction necessary for reflection. Transparent glasses, on the other hand, can easily be equipped with mica discs, FEP, or Halar® coatings, which is particularly recommended for protection of the glass in the case of aggressive media or high temperatures.

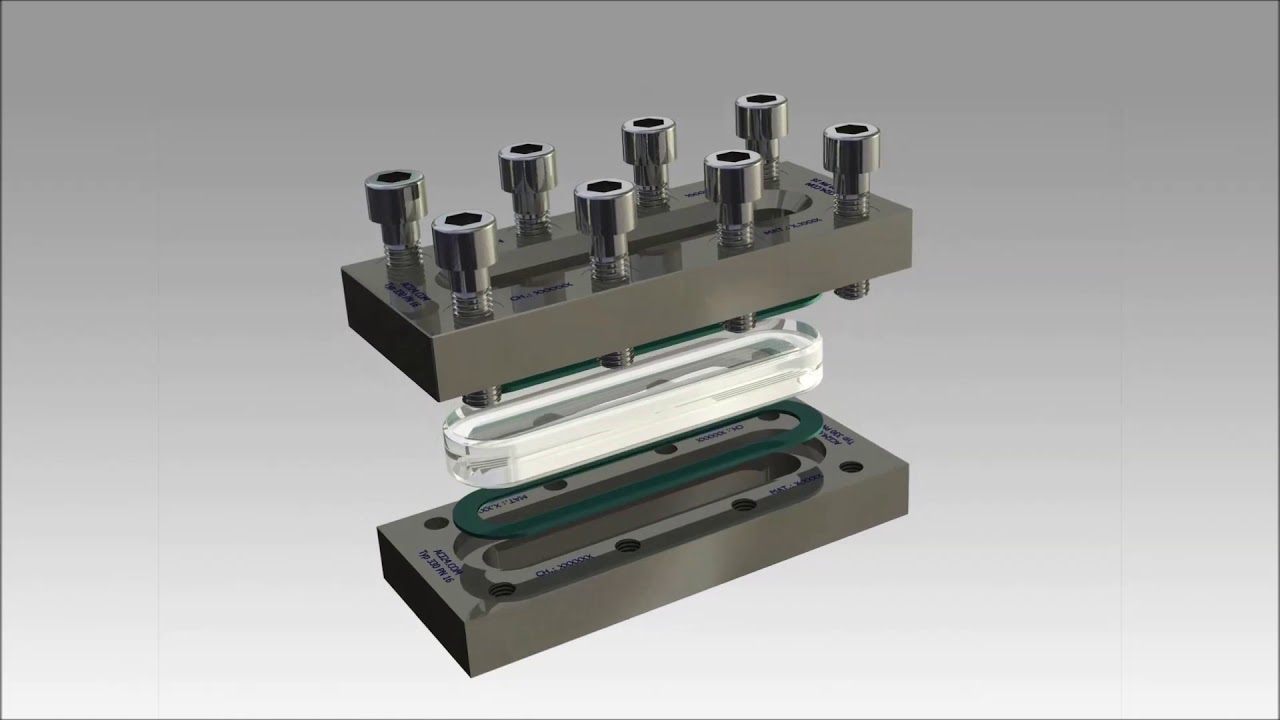

- Screws

- Cover frame

- Glass cushion

- Sight glass

- Gasket

- Base frame